In the precision machining industry, manufacturing an exact part is not enough: it is essential to ensure that each one meets the most demanding quality standards. That is why the quality department becomes the heart of any machining company that aims to be competitive both nationally and internationally.

In this article, we explain what a quality department in machining is, what inspections it performs, which standards are relevant, and how at MSJ Technology, based in Barcelona, this area ensures that every part delivered exceeds our customers’ expectations.

What is the quality department in machining?

The quality department is responsible for verifying that the manufactured products comply with the technical specifications established by the client and with the applicable international standards.

Its role is not limited to a simple final check: it intervenes from production planning to the dimensional and functional control of each part, ensuring traceability and reliability throughout the process.

Main functions:

- Define inspection and verification protocols.

- Perform quality checks at each machining stage.

- Certify parts according to international standards

- Identify and correct possible deviations.

- Guarantee traceability of each batch or component.

Importance of quality Control in Machining

Why is this department so crucial in the precision machining sector?

- Industrial safety

In sectors such as rail, aerospace, or energy, even the smallest deviation can cause critical failures. - Business reputation

Companies that ensure consistent quality generate customer confidence and open doors to new markets. - Cost reduction

Early detection of errors avoids returns, rework and delays in the supply chain. - International competitiveness

International customers demand strong certifications and quality processes before accepting a supplier.

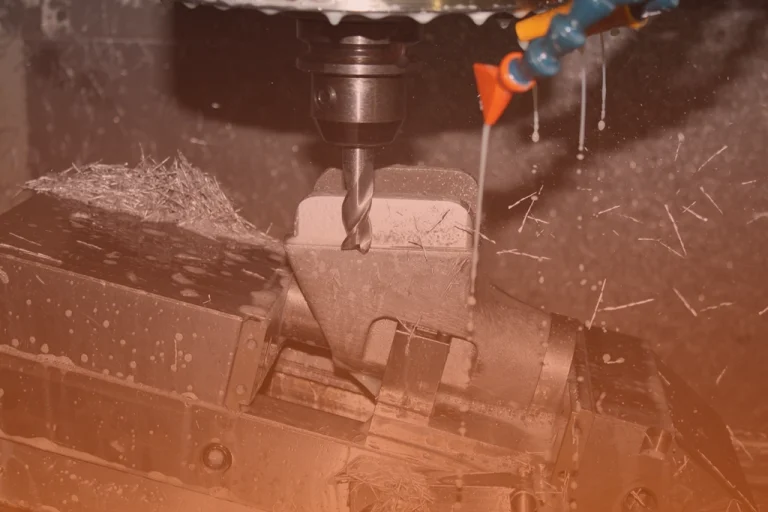

Quality controls applied to machining

The quality department uses various techniques and equipment to guarantee that each part complies with requirements.

Main controls:

- Dimensional control: measurement with calipers, micrometers and coordinate measuring machines (CMM).

- Visual inspection: detection of surface defects.

- Non-destructive testing (NDT): techniques such as liquid penetrant or ultrasonic to detect internal cracks.

- Functional control: verification that the part fulfills the function for which it was designed.

- Statistical control: analysis of samples to ensure process stability.

Standards and certifications in machining

The quality department must work under an internationally recognized regulatory framework. Some of the most relevant are:

- ISO 9001: quality management standard applicable to any industrial sector.

- ISO 14001: environmental management, increasingly required in tenders and contracts.

- ISO/TS 16949: specific to the automotive industry.

- AS9100: applicable to the aeronautical sector.

- UNE-EN ISO 13485: for manufacturers of medical devices.

These certifications not only guarantee quality, but also open doors to new international markets.

Quality and export: an inseparable relationship

In the global market, quality is the factor that makes the difference. A machining company that wants to export must guarantee that its parts meet the standards of the destination country.

The quality department is responsible for documenting, certifying and demonstrating that the components manufactured in Barcelona are suitable to compete in Germany, France, the United States or any other international market.

MSJ Technology: commitment to quality

At MSJ Technology we know that our customers’ trust depends on the quality of each part we manufacture. That is why our quality department is not a secondary area, but a strategic pillar of the company.

Our strengths in quality:

- Advanced measuring equipment that guarantees micron accuracy.

- Control protocols in each production phase.

- Complete traceability of each batch.

- Adaptation to international standards for export projects.

- Specialized metrology and inspection equipment.

Thanks to this structure, we ensure that every project, from prototype to large series, meets the highest industry standards.

Practical example: applied quality in automotive machining

In automotive projects, a simple variation in the diameter of a shaft can compromise an entire drive system. Our quality department works with minimum tolerances and calibrated measuring equipment to ensure that each part meets exact specifications.

This commitment not only avoids costly mistakes, but also generates the trust that allows us to work with international customers.

The machining quality department is the guarantee that each part delivered meets the highest standards of precision and reliability. It is not only about manufacturing, but also about certifying and ensuring that the final result meets the requirements of the customer and the international market.

At MSJ Technology, located in the metropolitan area of Barcelona, we make quality our best letter of introduction. Thanks to a specialized team, advanced technology and certified processes, we guarantee maximum precision parts for sectors such as automotive, energy, railway or aeronautics.

📞 +34 93 655 05 35

✉️ info@msjtechnology.com