We manufacture exactly what you need. No inventions. No mistakes. No surprises.

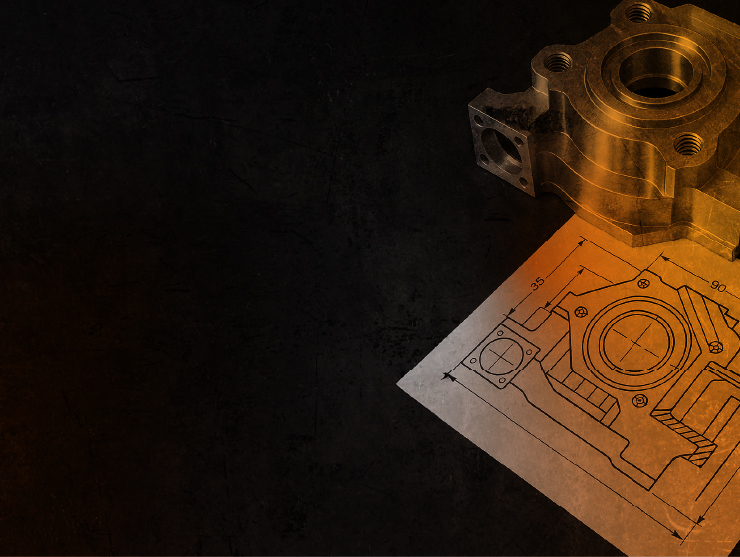

At MSJ Technology, when we talk about parts to drawing, we talk about precision, design fidelity and tailor-made industrial solutions.

What is an underplan part?

A part to drawing is a part that is manufactured exactly according to the technical specifications provided by the customer. It does not start from a catalog or improvise anything: it starts from a drawing. This drawing can be on paper, in PDF format or as a CAD file, and it clearly represents what needs to be manufactured.

Every line, every dimension, every notation is important. Because in industrial sectors such as hydraulics, chemicals, food or heavy machinery, the slightest deviation can mean a shutdown, a failure or a safety problem.

What information is contained in a technical drawing of a part?

A well-defined drawing is the basis for a part to fulfill its function perfectly. They usually include data such as:

- Measurements and tolerances: Exact dimensions, allowable margins and required accuracies.

- Type of material: Stainless steel, aluminum, brass, technical plastics… Each application needs the right material.

- Surface finishes: Polishing, shot blasting, grinding or other finishes to ensure good performance or aesthetics.

- Threads, bores, chamfers and critical areas: Detailed information on the functional parts of the part.

- Heat treatments or special coatings: such as nitriding, bluing, anodizing or galvanizing, depending on the environment in which the part will work.

What do you need to order a part off plan?

Ideally, you need a clear, up-to-date and detailed floor plan. But we understand that this is not always possible.

That’s why at MSJ Technology we can also help you develop that blueprint.

We can start from:

- A hand sketch

- An incomplete 3D model or file

- A physical sample piece

Our technical team will analyze your needs and will accompany you in the development of the necessary technical design to be able to manufacture it correctly. We help you to turn an idea into a useful and functional piece.

Why rely on MSJ for off-plan parts?

Because we have been doing the same thing for years: converting drawings into functional parts, with no margin for error.

We know the technical language

We know how to interpret drawings, talk to engineers and understand production needs. We don’t make assumptions: we ask questions to avoid mistakes.

Experience in all types of runs

We manufacture single pieces, short series and medium series, adapting to the real demand of each customer and without unnecessary costs.

We master demanding materials

From mild steels to stainless alloys, through brass, aluminum and technical plastics. We choose the material that best suits your project.

Real precision machining

We have modern machinery, rigorous quality controls and a team that knows that a part is only finished when it meets all the requirements of the drawing.

Commitment to deadlines and results

We know what it means to have a production stop or an out-of-time delivery. That’s why we are committed to every order, meeting deadlines and offering traceability if you need it.

When to order a part from a drawing?

- When you need a unique piece that can’t be bought ready-made.

- When you work in critical environments and there is no margin for error.

- When your project requires specific adaptations that the market does not offer.

- When the catalog falls short and you need a customized solution.

Do you have a piece in mind?

At MSJ Technology we make it possible.

Give us the plan and we manufacture it. And if you don’t have it, we will help you to define it.

📞 +34 93 655 05 35

✉️ info@msjtechnology.com

Piece under plane means confidence. It means precision. It means you decide how it should be, and we make it happen.